M/V Mark W. Barker

Statistics

Carrying Capacity: 26,000 Gross Tons

Overall Length: 639.0’

Year Built: 2022

Hull Depth: 45.0’

Beam: 78.0’

Engine Horsepower: 8,000

M/V Mark W. Barker

The first Great Lakes bulk carrier to be built on the Great Lakes in more than 35 years, M/V Mark W. Barker is also the first new build for Interlake since 1981.

This highly versatile River-Class vessel highlights Interlake’s long-term commitment to corporate social responsibility and sustainability.

All aspects of the vessel have been designed to ensure that it will have a low environmental impact to the Great Lakes and to those who work aboard.

Description

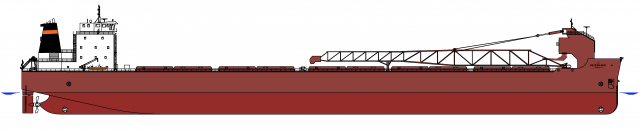

Constructed at Fincantieri Bay Shipbuilding in Sturgeon Bay, Wisconsin, the 639-foot ship will carry all types of cargo throughout the freshwater Lakes and River systems but was designed to navigate the tight bends of the Cuyahoga River in Cleveland.

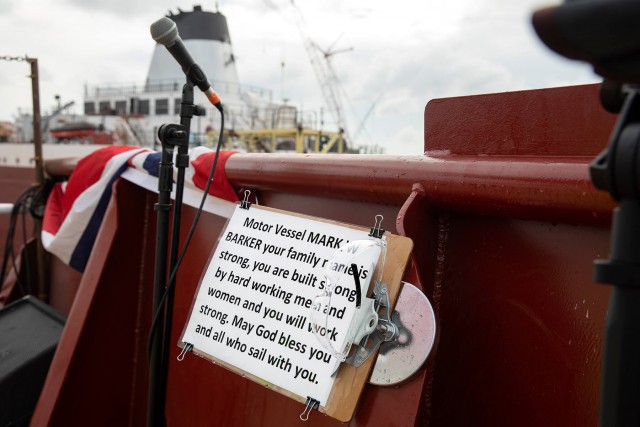

The Mark W. Barker is named for Interlake’s President and second-generation leader of the family-owned and -operated Interlake Steamship fleet.

She will be underway in Summer 2022 and officially christened in Cleveland.

The ship’s forward-looking design features include lowered emissions, high-efficiency propulsion and maneuverability, and enhanced cargo solutions to meet customer demands.

The Mark W. Barker will be the first ship on the Great Lakes with engines that meet EPA Tier 4 emissions standards.

She will be powered by twin EMD main engines generating 8,000 total horsepower that turn a single four-blade, controllable-pitch propeller through a Lufkin twin-input, single-output gearbox. She will have 1,000-hp Kongsberg bow and stern thrusters.

Her hull has been optimized for efficiency and all systems have been designed to ensure low energy consumption. A Kongsberg high-lift rudder optimizes the wake through the propeller.

The newest self-unloading bulk carrier has a unique cargo hold arrangement and cargo hatch covers designed for maximum cubic space and the ability to handle difficult cargoes.

Five large hydraulically controlled stackable MacGregor hatches, more commonly found on ocean-going vessels, offer enhanced flexibility with project cargoes and expedite loading operations.

Unlike most Great Lakes freighters, the Mark W. Barker has a square-shaped, flat-bottomed cargo hold instead of a traditional V-shaped angled bottom that funnels bulk cargo onto conveyer belts for offloading.

The combination of larger hatch openings and additional cargo hold space was designed with future cargoes in mind to include non-free-flowing bulk material such as wind-turbine blades.

In addition, the unloading boom is located on the forward end of the ship, offering flexibility for cargo operations in congested ports. Many Great Lakes customers find the forward boom more advantageous to allow placement of in preferred areas for access at their docks.

Interesting Facts

- Bulk-flow gates

- Variable speed drive for unloading conveyor